Описание продукта:

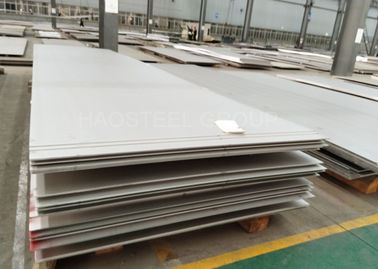

Нержавеющая сталь - это высококачественный продукт, предназначенный для удовлетворения различных потребностей различных промышленных применений. 316, 316L, 321, 317L, 347H, 2205, 2507 и 254SMO, этот продукт обеспечивает исключительную производительность, долговечность и коррозионную стойкость.Если вы нуждаетесь в 321 нержавеющей стали полосы или сплав стальной полосыНаш ассортимент изделий предназначен для обеспечения превосходных механических свойств и отличной отделки поверхности, что делает его идеальным выбором для требовательных условий.

Мы предлагаем гибкие ценовые условия, включая FOB, CIF и EX-WORK,предоставление покупателям возможности выбирать наиболее подходящий способ доставки и оплаты на основе их требованийТакая адаптивность в ценовом отношении позволяет доступным для глобальной аудитории стальной полосы, что облегчает бесперебойную торговлю и сотрудничество.

Одним из ключевых атрибутов нашей нержавеющей стали является ее впечатляющая прочность на растяжение, от 520 до 750 МПа.Этот диапазон гарантирует, что лента может выдерживать значительные механические нагрузкиВысокая прочность в сочетании с превосходной коррозионной стойкостью.Особенно в таких классах, как 321 нержавеющая сталь, обеспечивает долговечность и надежность даже в суровых условиях окружающей среды.

Линия из нержавеющей стали 321 особенно хорошо известна своей повышенной стойкостью к межзернистой коррозии и коррозионному растрескиванию при напряжении благодаря стабилизации, обеспечиваемой титаном.Это делает его отличным выбором для применения при высоких температурах и окислительной средеАналогичным образом, варианты стальных полос в нашей линейке продуктов предлагают сбалансированное сочетание прочности, выносливости и износостойкости.обслуживание специализированных промышленных секторов, которые требуют прочных материалов.

В дополнение к стандартным сортам, наша линейка продуктов из нержавеющей стали включает в себя передовые сплавы, такие как дуплексные нержавеющие стали (2205, 2507) и супераустенитные нержавеющие стали (254SMO).Эти сплавы обеспечивают превосходную устойчивость к выщелачиванию, коррозии трещин и коррозии стресса, что делает их идеальными для химической обработки, морских и оффшорных применений.Доступность такого разнообразного ассортимента сталей подчеркивает нашу приверженность поставке универсальных и высокопроизводительных продуктов.

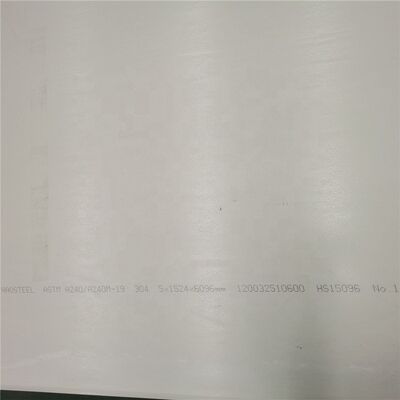

Наша лента из нержавеющей стали подвергается строгому контролю качества, чтобы обеспечить постоянство толщины, ширины и механических свойств.В результате такого высокоточного производства получается продукт, который не только соответствует отраслевым стандартам, но и часто превышает их. требуется ли тонкая лента из нержавеющей стали для электронных компонентов или более толстая лента для тяжелой конструкции,наша линейка продуктов оснащена для выполнения этих спецификаций с превосходством.

Подводя итог, предлагаемая нами лента из нержавеющей стали является универсальным, прочным и прочным материалом, подходящим для широкого спектра промышленных применений.включая очень востребованные варианты 321 из нержавеющей стали и сплавной стали, клиенты могут доверять качеству и производительности продукта.наша стальная лента является оптимальным решением для предприятий, ищущих надежные и эффективные металлические ленты продуктов.

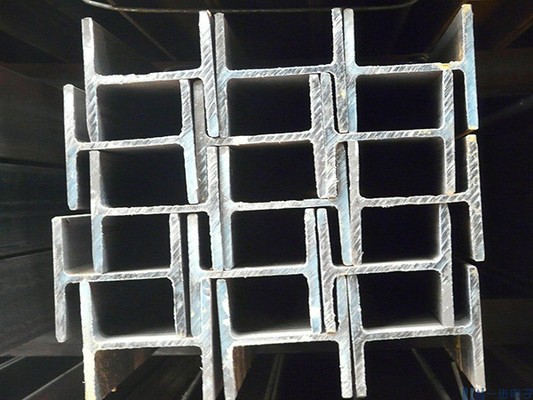

Применение:

Нержавеющая стальная лента, происходящая из Шаньдун, Китай, является универсальным и высокопрочным материалом, широко используемым в различных отраслях промышленности из-за его отличной коррозионной стойкости и прочности.Доступно в толщинах от 0 до.02 мм до 3,0 мм, эти ленты удовлетворяют широкому спектру применений, от тонких высокоточных инструментов до прочных промышленных компонентов.обеспечение плавности и точности, которые отвечают строгим требованиям производственных процессов.

Среди популярных вариантов, лента из нержавеющей стали 304 известна своей превосходной коррозионной стойкостью и формальностью, что делает ее идеальной для применения в бытовой технике,кухонное оборудованиеЕго способность выдерживать высокие температуры и сопротивляться окислению делает его подходящим для использования в теплообменниках и химических контейнерах.с более низким содержанием углерода, обеспечивают повышенную свариваемость и предпочтительны в производственных процессах, где часто проводится сварка, например, в строительных материалах и конструктивных компонентах.

Полоса из нержавеющей стали 316Ti, обогащенная титаном, обладает превосходной стойкостью к коррозии при высоких температурах,что делает его отличным выбором для морской среды и химической промышленностиОн обычно используется в производстве теплообменников, сосудов под давлением и трубопроводов, где ожидается воздействие суровых условий.Титановая стабилизация также гарантирует, что лента сохраняет свою целостность во время длительного воздействия повышенной температуры.

В промышленных условиях ленты из нержавеющей стали имеют решающее значение для производства пружин, зажимов и точных инструментов из-за их прочности и гибкости.Толщина 02 мм, идеально подходят для применений, требующих тонких, легких, но долговечных материалов, таких как электронные компоненты, медицинские устройства и декоративные отделочные части.0 мм используются в конструктивных арматурах и тяжелой промышленности.

В целом, лента из нержавеющей стали из Шаньдун, Китай, является надежным материалом для различных случаев применения и сценариев.или специальных химических и морских применений, варианты 304 нержавеющей стали, 304L нержавеющей стали и 316Ti нержавеющей стали обеспечивают индивидуальные решения, отвечающие конкретным требованиям к производительности и долговечности,обеспечение долгосрочного качества и эффективности.

Настройка:

Мы предлагаем комплексные услуги по настройке продукции для продукции из нержавеющей стали, чтобы удовлетворить ваши конкретные требования.Наши варианты плоской стальной ленты и сплавной ленты доступны в различных стальных классов, включая 201, 202, 301, 304, 304L, 316, 316L, 321, 317L, 347H, 2205, 2507 и 254SMO, гарантируя высочайшее качество.Вы можете выбрать из различных краев отделки, такие как Mill Edge или Slit EdgeНаши конкурентоспособные ценовые условия включают FOB, CIF и EX-WORK, чтобы обеспечить гибкие варианты закупок.Если вам нужны 304L нержавеющей стали полоски или другие сплав композиции, наши услуги по настройке гарантируют точность и надежность вашего проекта.

Упаковка и перевозка:

Наши изделия из нержавеющей стали тщательно упакованы, чтобы обеспечить максимальную защиту во время транспортировки. Каждая полоска сначала завернута защитным слоем для предотвращения царапин и коррозии.Затем обернутые полоски надежно помещают в прочные деревянные ящики или металлические катушки, в зависимости от размера и количества заказанного.

Для доставки мы используем надежных логистических партнеров, специализирующихся на обработке металлических изделий.Убедитесь, что нержавеющая сталь прибывает в пункт назначения в идеальном состоянии..

Мы также предлагаем индивидуальные решения упаковки по запросу для удовлетворения конкретных требований клиентов.мы стремимся предоставить услуги по упаковке и доставке, которые гарантируют качество наших нержавеющих стальных полос.

Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!  Ваше сообщение должно содержать от 20 до 3000 символов!

Ваше сообщение должно содержать от 20 до 3000 символов! Пожалуйста, проверьте свою электронную почту!

Пожалуйста, проверьте свою электронную почту!